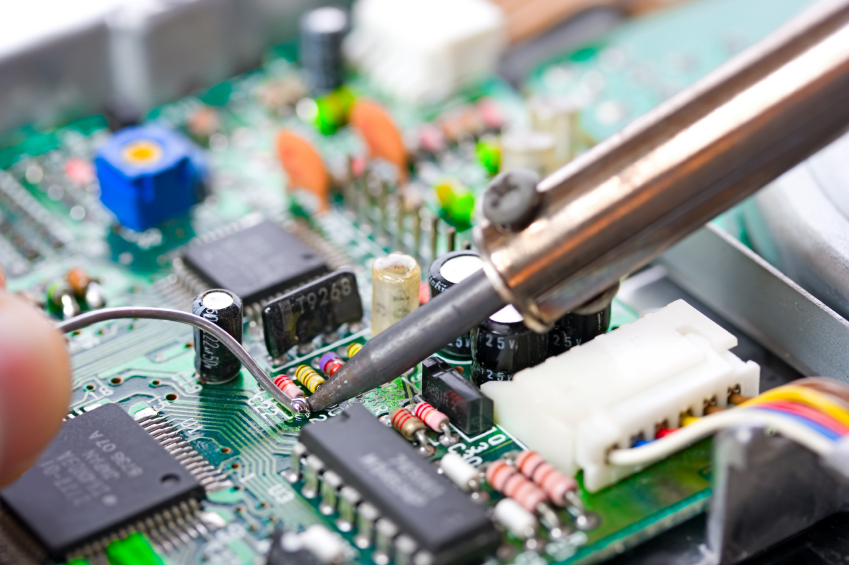

Training in High Reliability Soldering Techniques

Training in High Reliability Soldering Techniques (THT et SMT)

Advance and Intermediate Skill level for Operators

At the end of the Training the student’s will received:

- A training Handbook

- The Circuit that they assembled during the training

- A Certificate of our Company

Note that all the Workmanship training will be inspected and evaluated by the instructor on a monitor during the duration of the course.

Evaluation of your employees may be provided if required by your company.

Special Training adapted for your need’s on demand.

We offer these Trainings in French, English, and LSQ (Quebec Sign Language)

Call us for further Information and the prices will surprise you…

Content:

- Evaluation (1/2 Hour)

- DVD VT43 (1 Hour)

- Soldering and Desoldering Techniques

- Different alloys with Lead and Lead Free (RoHS)

- Different Fluxes and their uses and cleaning process

- Different Soldering irons and their characteristics

- The proper Tip to be used depending of the Thermal Mass.

- The Standards IPC-A-610 & ANSI-J-STD-001

- Preparation of wires

- Soldering to Turret, Cup, Hook and Pierced Terminals

- Preparation and Soldering of Axial and Radial components

- Soldering Dual Inline Package (DIP)

- Different method for removing components with desoldering irons and desoldering braid

- How to remove component with large thermel mass using a Infrared Convection Hot-Plate

- Modifications & Repair with Jumper wires

- Inspection according to the Standards ANSI-JSTD-001 & IPC -610

Day 2 and 3 SUFACE MOUNT TECHNOLOGY (SMT)

Installation, Rework and Extraction

Content:

- The Prevention of Electrostatic Discharge (ESD)

- Surface Mount Component Identification

- Installation and Removal of Chip Components (size 201 to 1206) With Special Tools and Standard Tools

- Installation and Removal of Gull Wing Components With Special Tools and Standard Tools

- Type of Components: SC90, SOT, SOIC, PLCC, QFP, TQFP, TSSOP (fine Pitch)

- Installation and Removal of J-Lead Components With Special Tools and Standard Tools

- Methods using convection for installation and removal of components

- Modifications & Repair with Jumper wires

- Evaluation by the Standards ANSI-JSTD-001 & IPC -610

The Training will be provided by highly skilled IPC Certified instructors

(A-610, WHMA A620, ANSI-J-STD-001, IPC 7711/7721)

Hand tools solder station and microscope for each workbench. Circuits, Components and a Handbook are provided.