J-STD-001 Certified IPC Specialist

J-STD-001F Certified IPC Specialist

COURSE DESCRIPTION: J-STD-001 Certified IPC Specialist is a comprehensive, knowledge-basedseries of Courses that certify students to the

methods and procedures presented in the J-STD-001 document. Designed for experienced operators, the series helps workers Interpret the J-STD-001 specification through lecture, demonstration and labs.

The program is divided into5 one day modules, each covering a different Technology or area of soldered electronic assemblies. Students may be trained and certified in any combination of modules that includes module 1. These courses

address all three classes of manufacturing in Wires andTerminals, Through-hole and Surface Mount Technologies.

*For on-site training, this course can be taught in either Lead or Lead-free Solder.

All the exams will be done online directly on the IPC Training center to avoid Certificate typo errors

and fraud, We will bring all of the computers and if done on your premises you company should

provide Internet Access.

Course outline:

Course outline:

DAY 1 – MODULE 1 OVERVIEW OF J-STD-001

Students will learn the requirements of J-STD-001 and related standards as they apply to operators and inspectors

involved in the assembly of products to the requirements of J-STD-001.

Module 1 is a prerequisite to all other modules.

- Course Overview

- Safety

- EOS/ESD

- Classes of Equipment

- Solder Theory

- Solderability

- Solder Flux and Solder Alloys

- Facilities, Tools & Equipment Training

- PTH – Assembly/Solder

- Surface Mount Technology

- Cleaning

- Module 1 Review

- Module 1 Examination

DAY 2 – MODULE 2 – WIRES & TERMINALS

Students will learn the requirements of J-STD-001, and demonstrate the skills for stripping and tinning wire and hand soldering wires of different gauges to various types of commonly usedsolder terminals.

- Wire Preparation

- Solder to Terminals

- Terminal Inspection

- Wire & Terminal Demonstration

- Wire & Terminal Lab

- Module 2 Review

- Module 2 Examination

DAY 3 – MODULE 3 – THROUGH-HOLE TECHNOLOGY

Students will learn the requirements of J-STD-001, and demonstrate the skills for preparing and mounting Through-Hole

components to PWBs.

- Lead Preparation

- Component Mounting

- PTH Inspection Criteria

- PTH Soldering Demonstration

- PTH Lab

- Module 3 Review

- Module 3 Examination

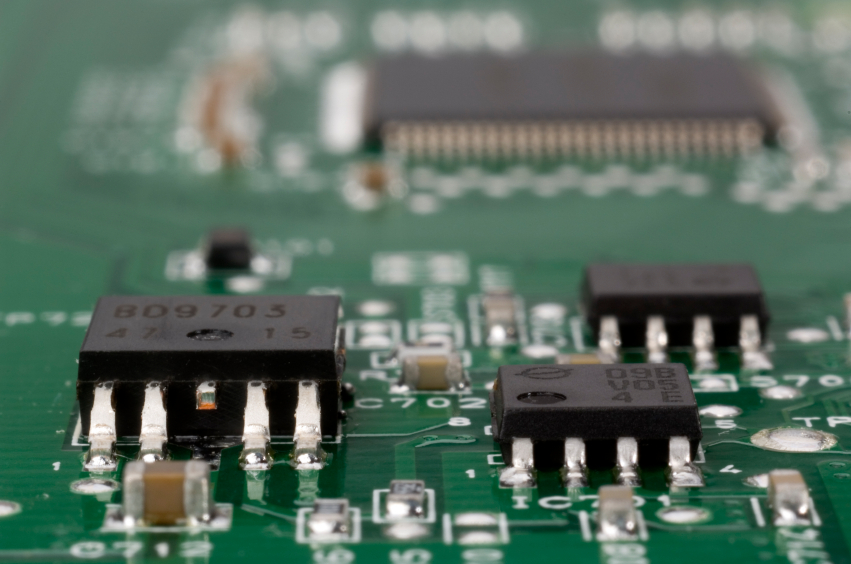

DAY 4 – MODULE 4 – SURFACE MOUNT TECHNOLOGY

Students will learn the requirements of J-STD-001, and demonstrate the skills for preparing and mounting Leaded and Leadless Surface Mount components to PWBs.

- SMT Criteria

- SMT Inspection Criteria

- SMT Demonstration

- SMT Lab

- Module 4 Review

- Module 4 Examination

DAY 5 – MODULE 5 – INSPECTION METHODOLOGY

Students will learn the quality and inspection requirements of J-STD-001.

- Theory of Inspection, SPC

- Defect Definition andDisposition

- Inspection Skills Demonstration

- Inspection Skills Lab

- Module 5 Review

- Module 5 Examination

Hand tools soldering stationof new generation andmicroscope for each workbench. Circuits, Components and a Handbook are provided.

An IPC Certificate will be given to the Student at the end of Training if he or she succeeds.

The IPC Certificate is valid for 2 Years and during that time you can add any modules.